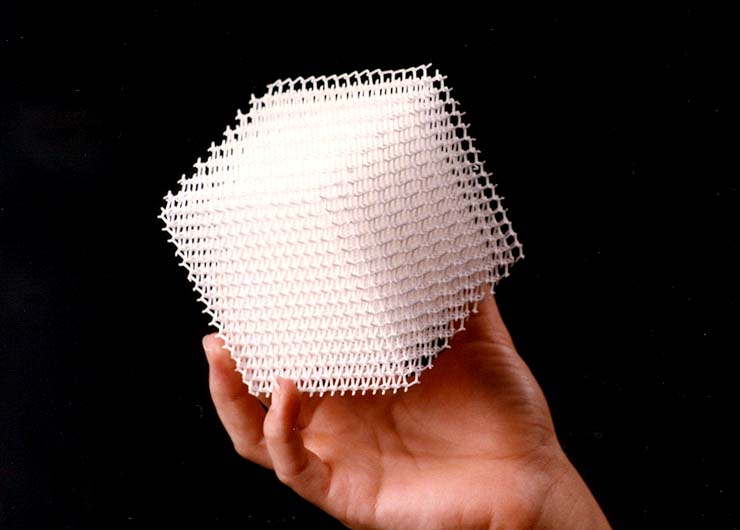

Tech types have long been seduced by the possibilities of 3D printing. The idea of bringing a dream to life as a physical object is an incandescent one, but when combines with electronics printing, something truly remarkable is achieved.

Printing in 2D is a standard everyday task, but printing in 3D has staked its claim at the forefront of modern technology. The machine, a stereo lithography printer, or SLA for short, takes computer imaging and slices it into minute cross sections. Then inside the section of machine that builds the on screen 3D image, super thin layers of a liquid polymer start stacking on top of each other according to the image onscreen. The process continues, even unmonitored, until a complete 3D image or replica of the model is complete. It is the ultimate design advancement in CAD computing.

The first high-profile melding of the two technologies is a small, unmanned air vehicle.

This is a breakthrough and particularly salient given the U.S. government’s constant talk about “drones.” As quoted in PC Magazine, Jeff DeGrange, vice president of digital manufacturing at Stratasys said, “If you can print electronics onto it, you can give it intelligence. And that’s what’s not been done today. That’s what’s so exciting about marrying the two technologies together.”

But what tops it all is that the U.S. military has taken the technology above and beyond to electron ics and robotics. For a couple decades now, the U.S. has invested in building drone war crafts that reduce the need for a human death toll to accomplish its military agenda. The drones are essentially ginormous flying robots that are manned from a remote area by robotics and IT specialists, programming the drones to do whatever they’re commanded to do. Now they have taken this new technology of 3D printing and electronic printing, which gives some form of artificial intelligence to whatever is made, and built a rapid prototype of a new drone that wouldn’t even really need a human or humans to man it remotely.

ics and robotics. For a couple decades now, the U.S. has invested in building drone war crafts that reduce the need for a human death toll to accomplish its military agenda. The drones are essentially ginormous flying robots that are manned from a remote area by robotics and IT specialists, programming the drones to do whatever they’re commanded to do. Now they have taken this new technology of 3D printing and electronic printing, which gives some form of artificial intelligence to whatever is made, and built a rapid prototype of a new drone that wouldn’t even really need a human or humans to man it remotely.

What that means for our enemies is nothing good, as the machines would do all the air and foot soldier work for us, and they would never see our military coming. Being able to build and imprint AI on almost anything simultaneously is an incredible marriage of technologies. The rapid prototype is the first of its kind, and an astonishing testament to engineering capabilities. An SLA machine that can not only build a 3D model but also electronically print layers of electrical intelligence onto and into the 3D parts it builds is far and away the most amazing advancement since computers went from giant rooms of server boxes to laptops in personal living rooms. It is at that level of astonishing advancement. Oddly enough, in another 20 or 30 years, we probably won’t even blink twice about this advancement, as something even more out of the realms of science fiction now will become a reality then.

It will be great to see this technology in use for something other than military. As it stands, only the two separate technologies are available presently to everyday companies for use. United, they could change medical machinery and equipment, household appliances, even the vending machines at work that eat your money and don’t give you what you paid for. Perhaps it will reach us just when more advances have been made, when robots actually do exist in our homes or our homes are “smart homes” using the technology that was married first for the military for warfare purposes. I can’t wait to see what comes next—can you?

Leave a Reply